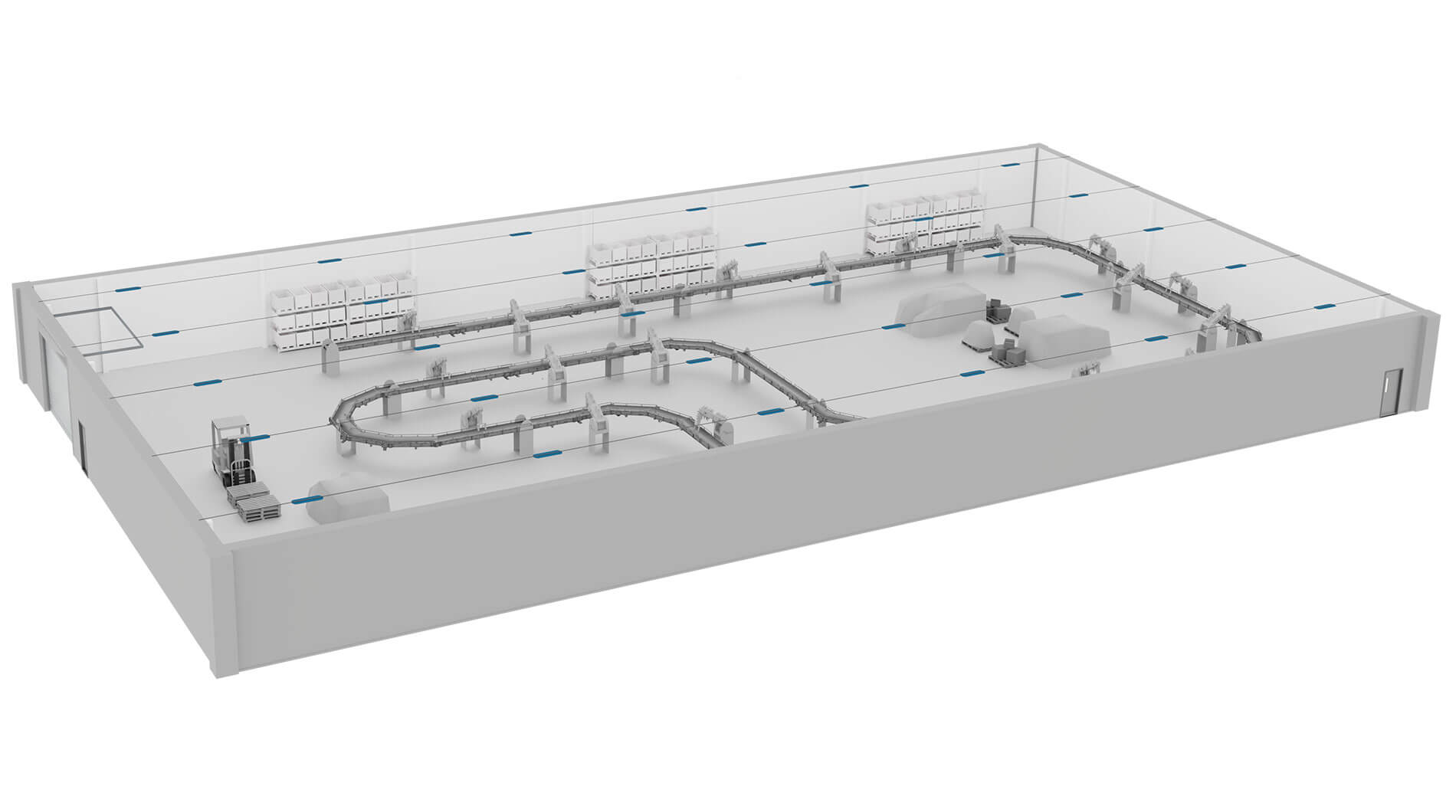

Processing (High Risk)

In areas where food is processed openly, the Food Hygiene (General) Regulations require that luminaires near the product be housed in an enclosure which prevents the lamp or any part of the luminaire accidentally falling into the product.

The luminaires should be easily cleaned and be constructed of materials with finishes which will withstand frequent cleaning and possibly hosing down (IP55 minimum) often with corrosive chemical agents.

The luminaires should have a minimum horizontal surface area upon which dust can rest and no crevices in which fungus can grow.

For recommended lux levels please see CIBSE : SLL Lighting Guide 1 - The Industrial Environment (2012, updated 2018)

Illumination Levels

The requirements will vary depending upon the industry, but typical values are 200 - 300 lux in automated process areas, 300 - 500 lux where manual operations take place and 500 - 750 lux in inspection areas.

The CIBSE: SLL Lighting Guide 1 - Industrial Environment 2018 provides guidance for specific industries and processes, although many companies have their own engineering standards.

| Application | Minimum maintained mean illuminance (lux) | Illuminance uniformity (minimum/average) |

|---|---|---|

| Process areas | 300 | 0.60 |

| Sorting and washing of products, milling and mixing | 300 | 0.60 |

| Automatic processes | 200 | 0.40 |

| Inspection | 750 | 0.70 |