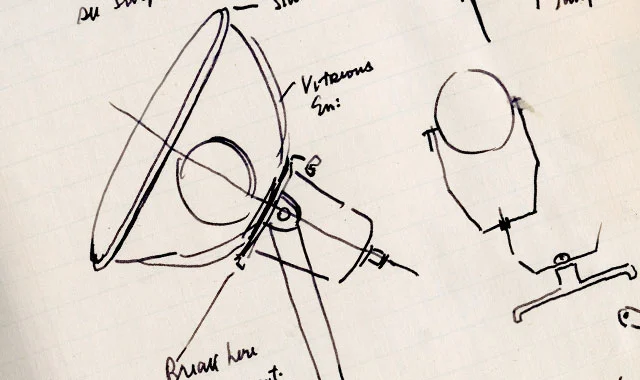

The first Thorlux pendants were produced in the 1930’s. Spun by skilled craftsman in the factory in Birmingham the pendants were finished in a quality, durable vitreous enamel coating.

Although technologies have progressed rapidly in many areas, traditional spinning techniques are still part of the Thorlux culture, and an integral part of the manufacturing process.

The Spinning Department still produces components by hand in both steel and aluminium for around 50 product ranges, totalling approximately 50,000 items each year.

Originally equipped with high wattage tungsten lamps, and later (as the technologies developed) with mercury and sodium discharge lamps, tens of thousands of Thorlux pendants were used to illuminate industrial spaces and warehouses.

The longevity and quality of the range is demonstrated by the numbers that are still in circulation today.

The range combines traditional hand-spinning with energy efficient LED technology to produce a high-quality product worthy of its heritage.

The reflector for every pendant is spun from mild steel using the original machines and tooling, and is finished in original-colour vitreous enamel for a long-lasting high gloss finish.

LED lamps complement the longevity of the product and offer significant energy savings compared to the original lamp types.